Sls 3d Printing Fashion Iris Van

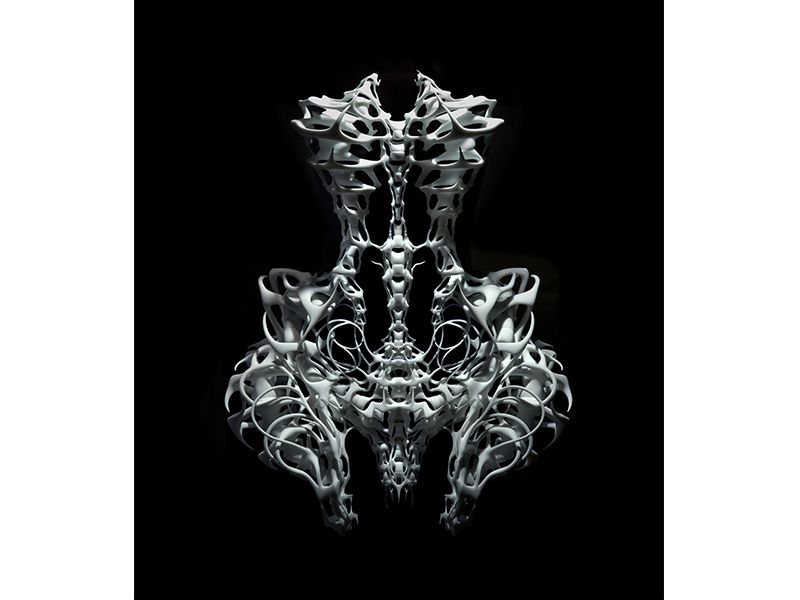

In 2011, Iris van Herpen made a splash when she debuted a 3D-printed apparel—ane of her first 3D-printed pieces—at Paris Haute Couture Fashion Calendar week. The rigid garment resembled intricate white cloth scrunched-up into the shape of a Rorschach test. It was named 1 of the year's best inventions past Fourth dimension mag.

Van Herpen was the showtime designer to send 3D-printed couture down the runway, first in 2010. Since and so, 3D-press has get a hot new tool in the fashion manufacture, with major designers creating geometric cutout gowns, stiff and shiny trims and garments that resemble skeletons or Medieval armor. These innovations are mostly for runways, though a few have filtered into prepare-to-wear. The luxury brand Pringle of Scotland has woven 3D-printed elements into the patterns and cuffs of its sweaters.

"Iris van Herpen: Transforming Fashion," the starting time major exhibition of the designer's piece of work, will open up at the Loftier Museum of Art in Atlanta on November 7. The exhibition is a comprehensive survey, featuring 45 of van Herpen's most groundbreaking outfits from 2008 to the present, along with music and videos from her runways shows.

3D-printing technology has been effectually since the 1980s, and architects, engineers and industrial designers take been using the printers, which create objects layer by layer, to create models and prototypes for decades. There was an explosion of interest in the technique a few years ago, every bit the engineering science became more affordable and abode printers debuted.

Van Herpen, who is in her early 30s, had a meteoric rise in the fashion industry. She studied style at the ArtEZ Institute of the Arts, Arnhem, in the netherlands, and interned at Alexander McQueen in London. From an early on age, she was interested in bringing new materials and processes into fashion, and she began designing womenswear under her own name a twelvemonth after graduating from manner schoolhouse. At 27, she became the youngest designer named to the official calendar of Paris Haute Couture Fashion Week. Van Herpen pioneered the use of 3D printing for fashion, employing architects and engineers to help translate her designs into digital files that the printers tin can read. She began with rigid designs molded to the body and then expanded to flexible ones, every bit amend materials, such as the safe-similar TPU 92A-ane, became available.

"Iris van Herpen is fearless when it comes to experimenting with 3D printing and using the technology as a means to create the innovative designs that are her vision," says Sarah Schleuning, curator of decorative arts and design at the High Museum of Art, a Smithsonian affiliate museum. "She uses the technology non for its own sake, merely to attain spectacular effects that otherwise could non be realized."

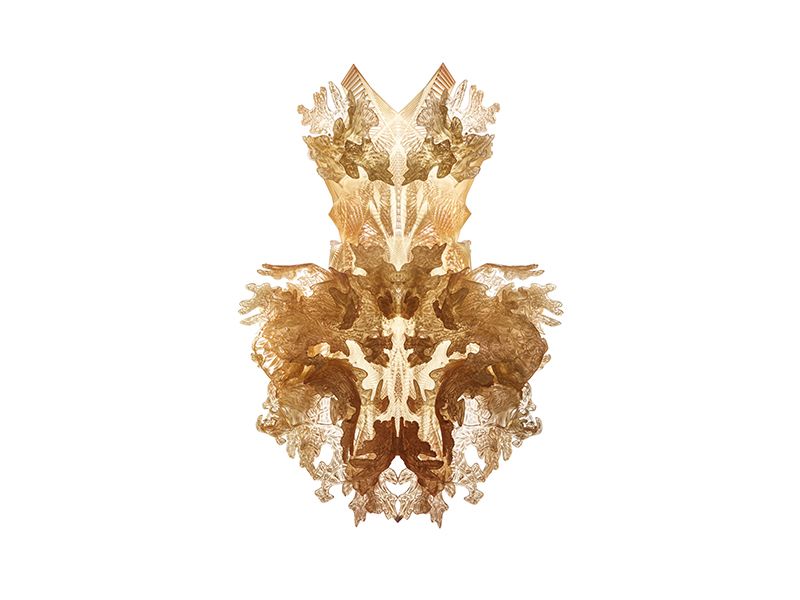

Adventurous mode icons such every bit Björk and Lady Gaga take been drawn to van Herpen'south pieces, possibly considering her piece of work looks like clothing sculpture. A acme from "Crystallization" (2010), her first collection to include 3D-printed elements, is rigid and looks like coral, with loops and ridges. A strapless clothes from 2014 nicknamed "Ice Apparel" resembles a unmarried formation of ice with an intricate texture. The piece was printed on a country-of-the-art, industrial 3D printer, and the material is a transparent resin. Since the wearer cannot sit downwards, the piece is clearly intended only for the runway.

"When you look at the dress, the trunk underneath and the translucent texture merge, and they become one," van Herpen writes in an email. "This is possible because the wearing apparel is two pieces, with seams but on the sides, so the texture looks organic."

Sometimes the 3D-printed fabric is not the garment'southward structure, but only an beautification, as in a 2014 dress that resembles a bird, with ribbons of 3D-printed cloth layered similar feathers.

But 3D press is non without its challenges. Since van Herpen'south designs are elaborate, the digital files take a long time to create. And she can't meet the finished product until she receives information technology back from the printing company.

"It remains a surprise how the dress will look," she writes. "In the past, I printed a apparel then found out it didn't await good in the material I chose."

Equally new materials emerge, designers have to learn their limitations, through experimentation. Jenny Wu is an architect who launched her own 3D-printed jewelry company, LACE, in 2014. Her work is printed in a variety of materials, including elastic nylon, difficult nylon and stainless steel. "The tolerances are very different," Wu says. "Initially, my design might come dorsum crumbled into pieces, or it might come back perfect. You lot have to learn to design to the material."

Van Herpen'due south 3D-printed designs inspired other designers, including Francis Bitonti, who printed a gown for Dita Von Teese featuring more than than 3,000 unique, articulated joints, and Karl Lagerfeld, who adorned iconic tweed Chanel suits with 3D-printed details earlier this year. Fashion pattern students, too, are eager to experiment with 3D printing, though the cost oft puts commercial 3D printing across their reach, and they need to learn the modeling software.

This spring, Danit Peleg, a educatee at Shenkar College of Engineering and Design in State of israel, used a domicile 3D printer to create 5 garments for her graduate collection. Because the home printer was pocket-size, she had to impress the material in pieces, and the project took more than 2,000 hours. The finished garments, made with a prophylactic-like material called FilaFlex, feature geometric cutouts—some delicate, some large—in bold colors.

"I felt like I was tinkering with the futurity," Peleg says. "I believe we're going to see the mode manufacture change. Way houses will somewhen have downloadable patterns on their websites, so people can print their wearing apparel at abode. Nosotros won't need to do production in Asia."

Experts warn, even so, that it may take decades to arrive at such a future. Lynne Murray, director of the Digital Anthropology Lab at the London College of Fashion, says 3D printing for fashion is still a new concept. "It's a overnice idea, to exist able to 3D impress clothes at habitation, or at your local corner shop, only it won't be a reality in the next ten years," she adds. "Maybe in 20 years, and maybe then the dress you get will also be able to change color or alter shape." The Digital Anthropology Lab, which just opened this fall, gives the school's fashion students access to 3D printers, conductive textiles, wearable technology and body-scanning technology. Other major fashion schools, such as the Manner Institute of Technology, Central Saint Martins and Parsons School of Design, accept 3D printers and offer courses in how to use them.

"There will be a range of applications," Wu speculates, of the time to come. "There volition be things to download and impress yourself, simply you'll also exist able to become something really special that'southward designed by, and printed under the supervision of, an artist or fashion house."

"Iris van Herpen: Transforming Fashion" is on brandish at the High Museum of Fine art, a Smithsonian affiliate museum in Atlanta, through May 15, 2016.

0 Response to "Sls 3d Printing Fashion Iris Van"

Post a Comment